North sea, Germany

Doedijns was contracted by Euro-Rigging to engineer and install the hydraulic and control system for a pile gripper installation. The pile gripper for this project will be used for the placement of 67 XXL monopiles at the offshore wind park. Each monopile weighing up to 1300 tons, having a diameter up to 7.8 meters and a length of 85 meters. Handling monopiles with these dimensions asked for an experienced subcontractor, this is why Doedijns was asked to deliver the hydraulic system, including e-controls, for the pile gripper. Similar projects have been executed in the past, such as the West of Duddon Sands Offshore Wind Farm in 2013 and Sandbank 24 in 2015.

The challenge

Especially the length and weight of the XXL monopiles called for unique and specific requirements. Due to their 85 meters it is a challenge to restrain the monopile during placement using only one pile gripper. That is why two pile grippers, placed directly above each other, are used. These two grippers jointly bring the pile in the upright position and keep it there.

Not only the length of the XXL monopiles is a possible cause for instability, also the wave motion is a force that should be taken into account. To prevent damage to the complete construction, the installation has been executed with a motion compensation system. We thus had to compensate a greater amount of energy than the installed drive power of the Hydraulic Power Unit. Therefore the hydraulic engineering was a challenging job as well as the engineering of the software. Especially with eight cylinders in a diaphragm shape enabling to follow the pile in all directions.

“Even though we have an extensive experience in taking care of a complete package, the customer’s specifications and requirements are and will always be unique.”

The project

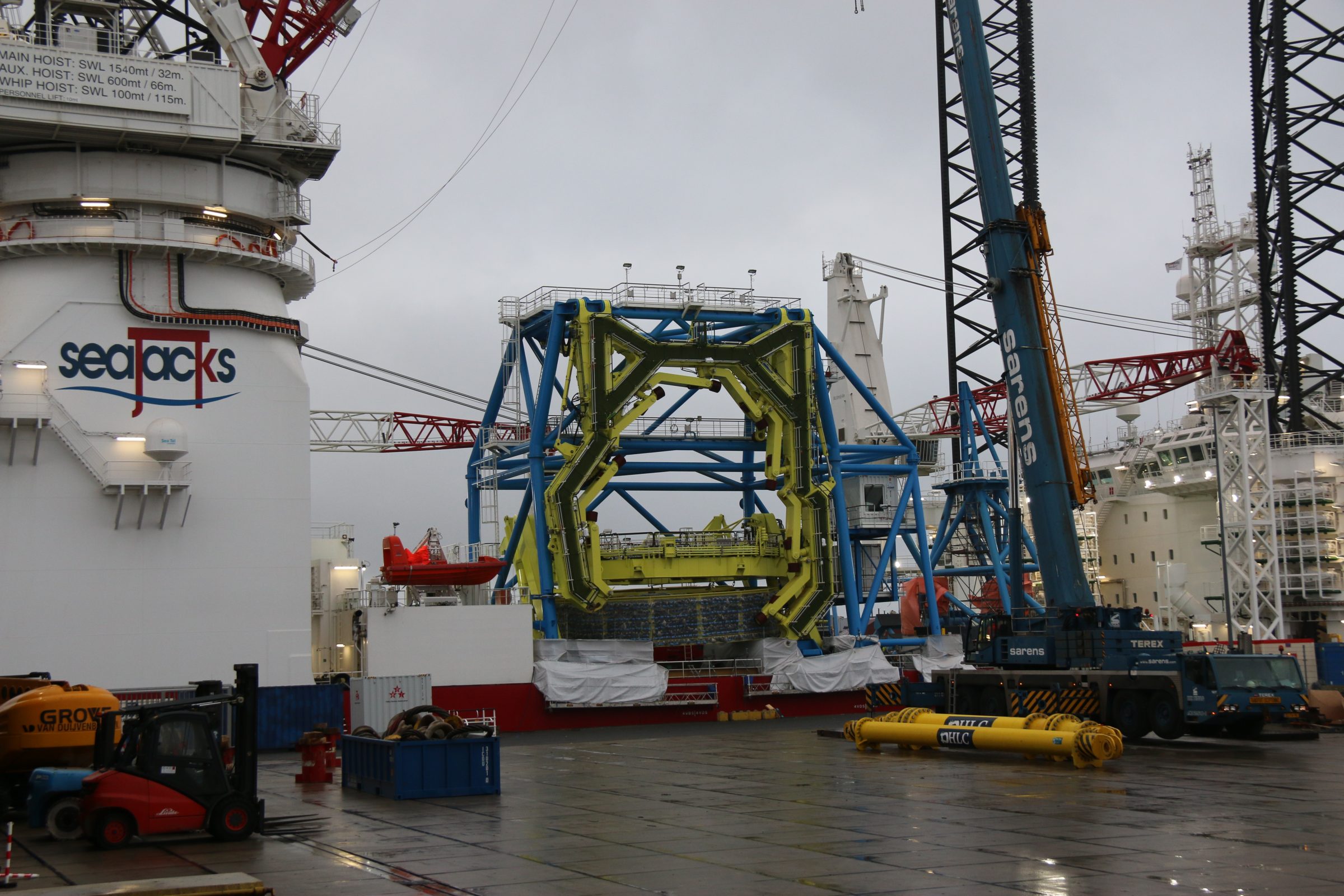

The offshore wind park is located in the German part of the North Sea, northwest of the island Borkum. With a production capacity of about 1.6TWh per year, this wind park is one of the largest offshore wind parks of the world. Each wind turbine foundation exists of a XXL monopile and a transition piece connecting the wind turbine to the monopile and creating a passage. After transportation from the production locations to the wind park, the monopiles were installed by the Seajack Scylla jack-up installation vessel using the pile gripper frame.

Doedijns took care of the project management, engineering, production, installation and commissioning of the hydraulic system. During the project we closely worked together with Euro-Rigging to ensure we got all the specific requirements right, preventing unnecessary surprises for the customer. Even though we have extensive experience in executing these kind of projects, we always create tailor made solutions seamlessly fitting the unique customer specifications and requirements.

We delivered

- Hydraulic Power Unit in High Cube container provided with 3x90kW power

- Installed cooler of 300kW

- Motion compensated diaphragma drive

- Over 30 manifolds

- PLC including software engineering and wireless remote control

- Software tested by means of a simulation model

- Cylinders up to size D500 and 4500mm stroke

- More than a kilometre of piping installed

Watch our project video here!