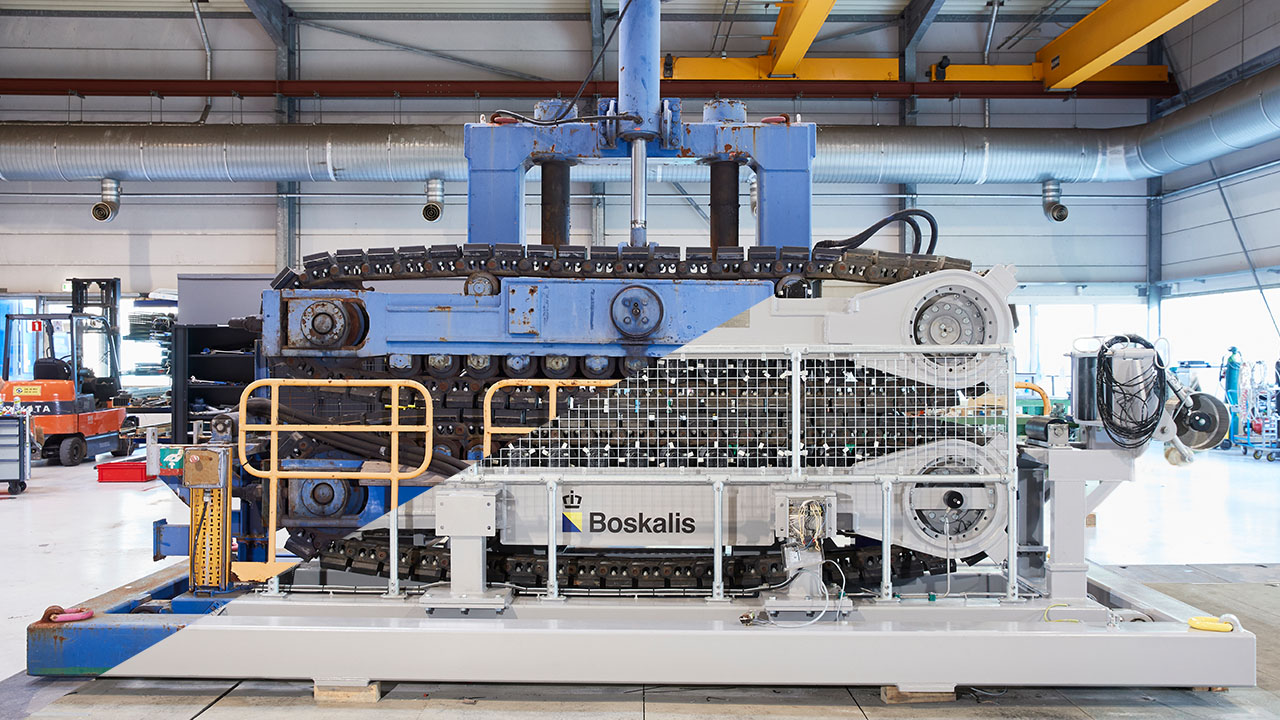

10T tensioner for cable laying vessel

At Doedijns we take our environmental responsibility very seriously. This is why we will always provide our customer with the most suitable solutions, from a cost-efficient perspective as well as from an environmental perspective.

With the circular economy in mind, overhauling is a profitable solution to extend the lifetime of a system significantly. Seeing Doedijns as an experienced service partner, Boskalis approached us to overhaul their 10T Tensioner.

Extended product lifetime

The tensioner was already in operation for 10 years but could be, after a thorough revision, put back in operation for a similar period of time. So instead of decommissioning the system, the tensioner was overhauled completely and upgraded to today’s standards. With the integration of a new hydraulic power unit provided with integrated electronic controls.

Within a timeframe of 14 weeks, the complete tensioner, including the hydraulic system, controls and mechanical parts, was disassembled, overhauled, reassembled and tested. By overhauling the equipment, the product lifetime is extended with minimum of 10 years.

Cost efficient hydraulic power unit

The tensioner will be installed on a cable laying vessel of Boskalis. A cable layer vessel is a deep-sea vessel designed and used to lay underwater cables for telecommunications, electric power transmission, or other purposes. The tensioner ensures the cable leaves the vessel at the correct speed. It is therefore utmost important that the motion of the tensioner is stable and controlled.

As a provider in power, motion and control solutions, Doedijns, has all the knowledge in-house to design and deliver a perfect fit hydraulic power solution for the tensioner. As a result, the tensioner is geared with a cost-efficient hydraulic power unit provided with integrated electronic controls which guarantees stable motion and control.

“As an official distributor, Doedijns has access to components of world’s leading hydraulic and pneumatic brands. This, in combination with the in-house knowledge of integrated systems, enables us to handle the complete scope, the complete revision including the full mechanical scope and the integration of the new HPU’, says Marinus Brouwer, Manager Services at Doedijns. ‘This way the customer is fully supported and is ensured the best suitable solution.”

Marinus Brouwer, Manager Services at Doedijns

The tensioner is delivered within time and to full satisfaction of the customer.