North sea, Norway

Doedijns received an order to supply the complete Upending Control System (UCS) for a Launch jacket currently being fabricated in the Netherlands. The jacket is destined for field development in the Norwegian central part of the North Sea.

We delivered

With the advent of the very large platforms developed for offshore oil use today it is no longer a matter of simply opening a few valves and lifting the top of the platform with a derrick barge to upend it. The sheer weight of these structures (17.000 tonnes in the case of the Gina Krog jacket) is beyond the capacity of the largest offshore crane ships operating today.

Even with a fleet of large lift cranes, the coordination and perfect sea conditions required would make a lift-flood method impractical and very expensive. Because of the large-size and cost of these platforms which must be set accurately in place under less than ideal sea conditions, much effort is required to design, detail, construct and operate reliable and versatile flooding systems.

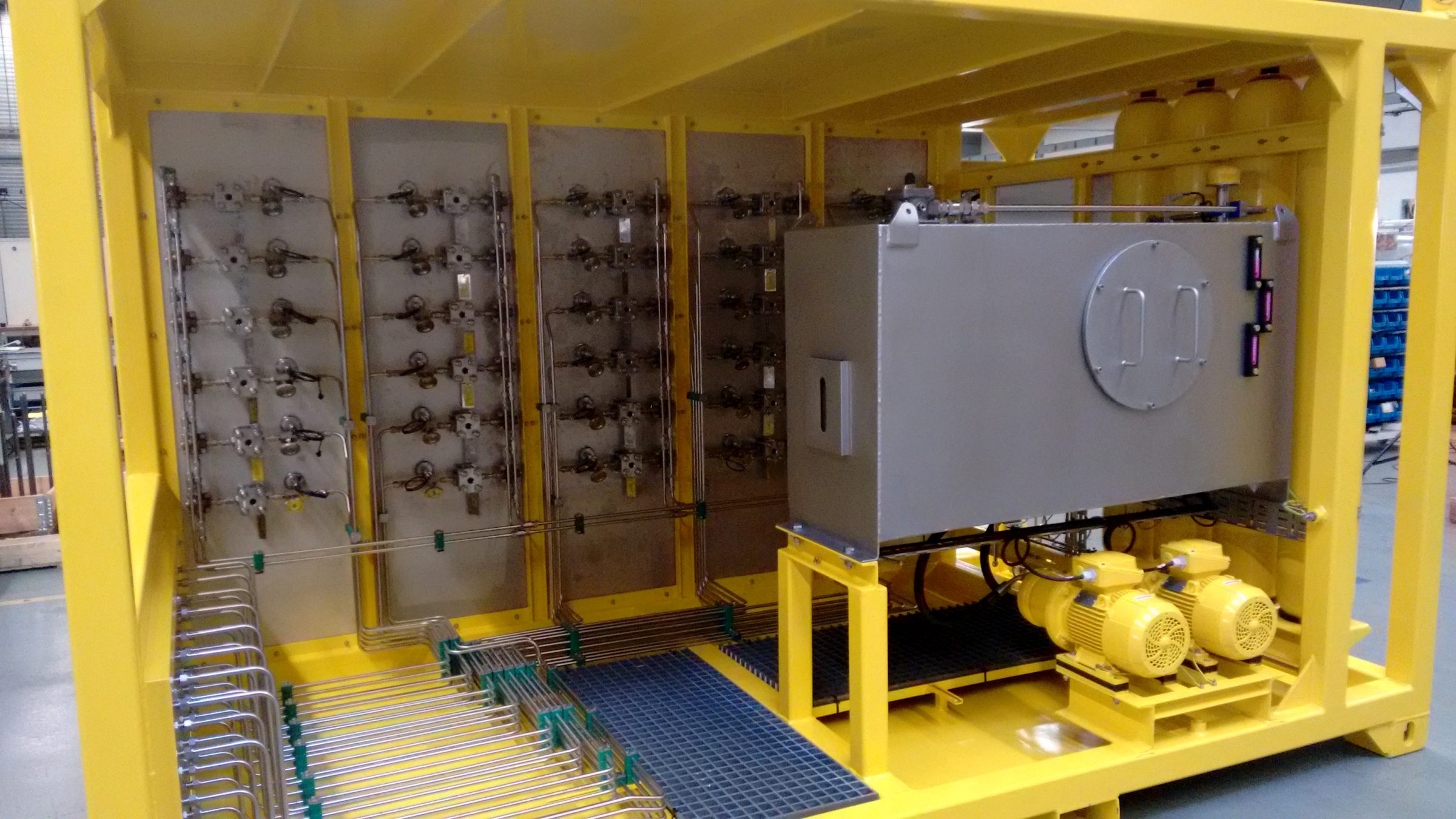

Doedijns will supply the complete Upending Control System and pressure monitoring system, which includes an Upending Control Center (UCC), Umbilical on winch and jackter interfacing, 3 compartment monitoring panels, 70 valve assemblies, 12″ rip-out diaphragms, 10 kilometer of different hydraulic hoses and all connecting components.

In addition to the supply of these components and systems, we took care of the complete project management for the design-supply of jacket critical installation equipment. This included the supervision during construction activities, performing overall site-integrity testing, managing and expediting of the sub-suppliers and interfacing with client, T&I company and end-user.

The project

Weighing 17.000 tons with a height of 142 meters, a footprint of 60 x 50 meters and a top of 40 x 30 meter, the Gina Krog jacket is the largest launch jacket ever built at a Dutch yard.

“This project is an example of the complex solutions we provide to our clients. Projects like this allow us to demonstrate our innovation and leadership in control automation and process packages whilst consolidating our position in the marketplace.”

Ronald van der Willik, Engineering Manager