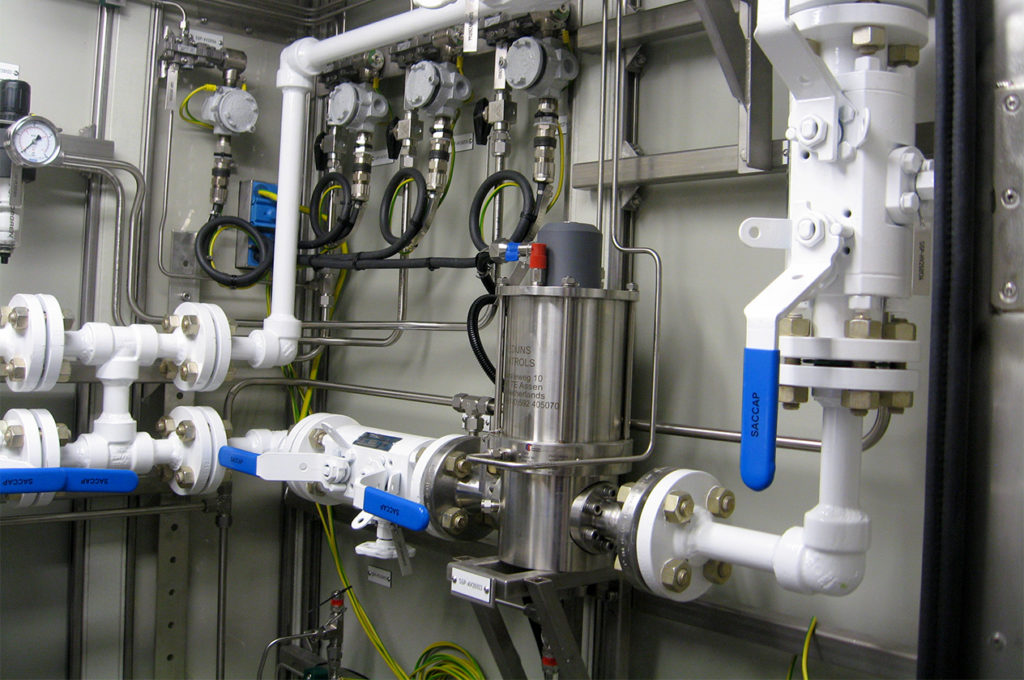

Besides complete sampling systems Doedijns also provides high quality sampling components. These products are all designed to operate in the harshest environments.

Sampling system components

Sample probes

In order to take representative pipeline samples it is important that the product is removed at the right location and in the correct manner. Doedijns has a long history of manufacturing sample probes for various products and applications such as liquid and gas. We can provide take-off probes that can be fixed to the pipeline or retractable ones.

Inline sample probes

Doedijns can provide a range of pneumatic and electrical inline samplers suitable for pipeline diameters from 4” to 52” with pressure ranges up to 1500lbs (250barg).

Fast-loop sample probes

A range of pneumatic and electrical fast-loop cell samplers is available from Doedijns. These fast-loop cell samplers are suitable for all pipeline diameters with pressure ranges up to 1500lbs (250barg). The 810 cell sampler is possibly the best of its kind on the market.

Wake frequency

To prevent vibration and damage it is very important that the sample probes are designed to operate outside of the natural frequency range. It is standard practise for Doedijns to calculate the wake frequency of the probes to ensure safe operation. Our calculations are in accordance with the ASME.

High and low pressure sample receivers

Samples are collected in atmospheric receivers, PSR10 or PSR20, with a volume of 10L or 20L (other volumes available on request). Doedijns has also a range of constant pressure cylinders available for collecting products with light ends (high vapour pressures). Doedijns manufactures and supplies high pressure sample cylinders and low pressure sample cans that meet the necessary pressure vessel directives worldwide.

Sample receiver mixing system

Just as important as the sampling system is the receiver mixing system. This very important link in the sampling chain is often overlooked. Doedijns’ mixing system for sample receivers is designed to meet the API 8.3 Standard Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products.

Receiver Weighing and monitoring system

This system enables accurate real-time analogue monitoring of collected samples. Used together with a suitable sample controller, performance calculations can be carried out in line with the API Ch8.2 and ISO 3171 sampling standards. Useful for predicting extractor failure and planning pre-emptive maintenance.

Doedijns' sample system controller (SC-10)

This PLC based system has been specifically designed to meet the requirements of the API 8.2 and ISO 3171 standards for automatic sampling. It covers all aspects of sampling control with the option of creating a log for future reference or disputes.

Get in touch with our experts

Would you like to get more information on our sampling system components and what we can do for you? Please contact us directly on +31 88 0912 600 or send us a message: